The key objective of calibrating a vernier caliper is to verify that its measurement error is within specified permissible tolerance limits and its accuracy is intact. These tolerance or error limits for vernier calipers are mentioned in its specification or data sheet provided by the manufacturer.

Accuracy specifications of the vernier are generally based on two standards DIN 862 or ASME B89.1.14 Error limits for 0.01 mm resolution digital vernier caliper are mentioned below. You can learn more about MME calibration methods and standards in our detailed guide ➜

| Measured Length (mm) | Permissible Error (0.01mm Resolution) | |

| DIN 862 (mm) | ASME B89.1.14 (mm) | |

| 50 | 0.02 | 0.02 |

| 100 | 0.02 | 0.03 |

| 150 | 0.03 | 0.03 |

| 200 | 0.03 | 0.03 |

| 300 | 0.03 | 0.04 |

| 400 | 0.03 | 0.04 |

| 500 | 0.03 | 0.05 |

| 600 | 0.03 | 0.05 |

| 700 | 0.04 | 0.06 |

| 800 | 0.04 | 0.06 |

| 900 | 0.04 | 0.07 |

| 1000 | 0.04 | 0.07 |

Now question arises that which error limits shall we follow? The answer is that manufacturer generally specifies the standard to which their vernier calipers complies. Manufacturers working under European Union regulation generally follow DIN 862 whereas manufacturers in America generally follow ASME B89.1.14.

If you are not sure or no information has been provided by the manufacturer then it is safe to follow DIN 862 due to its tighter limits. Furthermore if you are using vernier for precision or tight tolerance measurements then it is safe to use DIN 862 and if your use is general purpose than you can follow ASME.

In context of ISO 17025:2017 if the customer demands statement of conformity such as PASS/FAIL in the calibration certificate then in that case relying solely on limits discussed above will not be enough as standard requires a risk based approach for decision rule by considering uncertainty of measurement. A decision rule is a documented rule that defines how measurement uncertainty will be taken in to account when stating that results are within limit or out of limit.

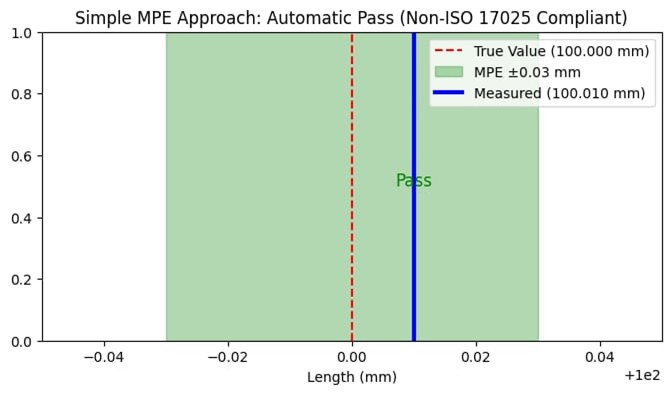

Let’s take an example of a vernier caliper calibrated using a gauge block having a nominal value of 100 mm. Reading on the vernier caliper was 100.01 mm. Permissible error values as per DIN 862 will be 0.03 mm. Measurement uncertainty (MU) reported by the lab was 0.02 mm.

Simple Approach (without considering MU)

Permissible Limits = 0.03 mm

Measurement Error = 100.01-100.000 = 0.010 mm which is < 0.03 mm, hence declared Pass.

Note that uncertainty of measurement has not been taken into account while making decision for pass or fail

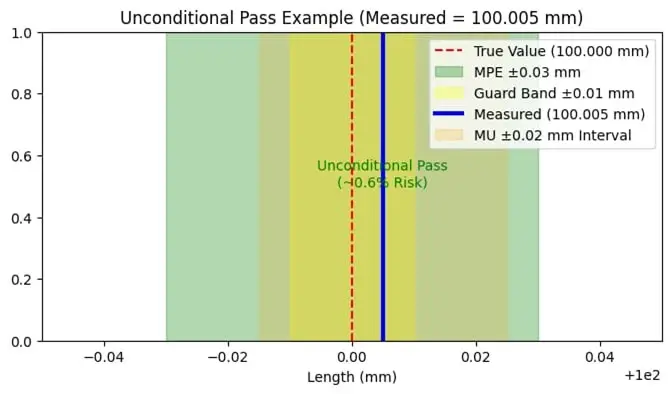

Risk-Based Approach (considering MU)

In this approach we will use a guard band based decision rule. The guard band will tighten the permissible limits i.e Acceptance Limits = Permissible Limits – MU. This will reduce risk of False Pass or Fail.

Now consider Measured Value = 100.005 mm with MU = ±0.02 mm

Permissible Limits = ± 0.03 mm

Acceptance Limits/Guard band limits = 0.03 mm – 0.02 mm = ±0.01 mm

MU Interval = [Measurement Error ± MU] = [0.015 – 0.025]

Measurement Error i.e 0.005 ≤ Acceptance Limit (0.01 mm)

Whereas MU interval is within permissible limits

Hence it will declared Pass Unconditionally.

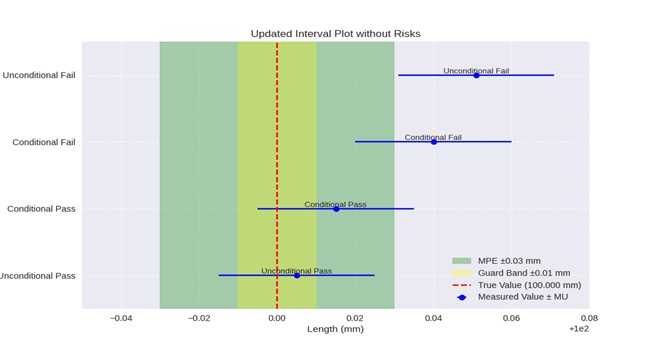

Here we interpret that for unconditional pass follows:

- Measured error is within acceptable limits

- MU interval i.e Measurement Error ± MU is within permissible limits

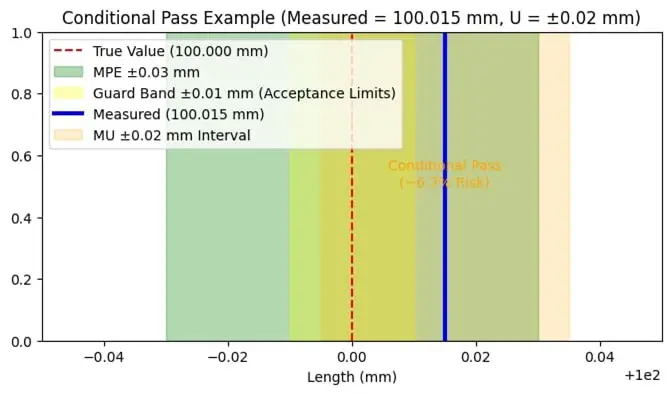

Conditional Pass

Now suppose measurement error was 0.015 mm with MU = ±0.02 mm

Acceptance Limits/Guard band limits = 0.03 mm – 0.02 mm = ±0.01 mm

The error exceeds guard band or acceptance limits of ±0.01 mm

Now

MU Interval = Measurement Error ± MU = [0.015 ± 0.02] = [0.005 – 0.035 mm]

MU interval upper limit (0.035) is > Permissible Limits 0.03.

So it will be a conditional pass. Here we can interpret the criterion for conditional pass as follows:

- Measurement error is outside acceptable limits

- MU interval partially exceeds the permissible limits boundary with small margin.

Similarly criterion for unconditional fail & conditional Fail are as mentioned below

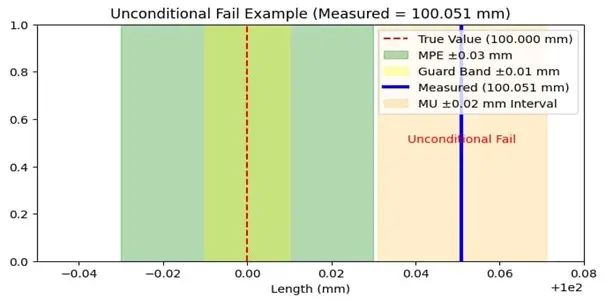

Unconditional Fail

- Measurement error is outside acceptable limits (guard band limits)

- MU interval clearly exceeds the permissible limits boundaries

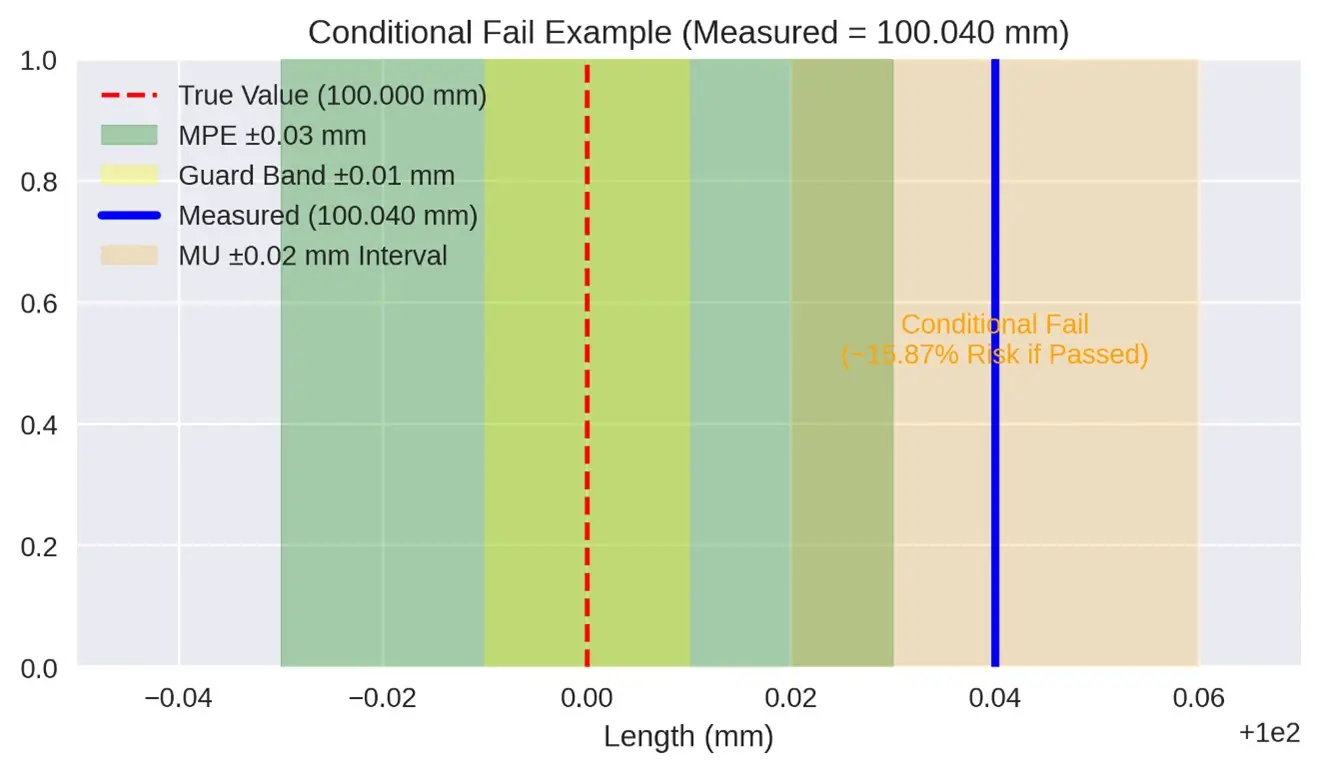

Conditional Fail

- Measurement error is outside acceptable limits (0.01 mm) and permissible limits (0.03 mm)

- MU interval partially exceeds the permissible limits boundary from upper or lower side

All four conditions discussed above can be summarized in the figure below