Complete Guide to Calibration of Measuring Instruments

Table of Contents

Table of Contents

What is Calibration?

Calibration is the process of evaluating the performance (accuracy) of an instrument by comparing it against another instrument of known accuracy (often referred to as a measurement standard or reference standard).

Example: Calibrating a Digital Vernier Caliper involves measuring standard gauge blocks. Gauge blocks of different sizes (e.g., 25 mm, 50 mm, 100 mm) are placed between the jaws of the vernier caliper, and the reading on the vernier’s display is noted. Suppose a 100 mm gauge block is measured, and the reading on the vernier’s display is 100.02 mm; the error will be 0.02 mm. These measurement results are then reported in the calibration certificate.

Error found during the calibration can be adjusted, provided there is provision in the instrument for adjustment. This is usually done if the error is close to or exceeds the acceptable tolerance limits provided in manufacturer specifications or published standards. Example: As per DIN 862 standard, acceptable tolerance limits for a Vernier Caliper at 100 mm are 0.03 mm.

Why Calibration is Important?

Due to continuous use over a period of time, errors in the instruments tend to increase due to wear and tear, also referred to as drift. Some contributing factors for this are:

Continuous use causes aging in mechanical moving parts, inducing wear and tear.

Example: A vernier caliper being used in a workshop for measuring mechanical parts may develop wear and tear in its sliding mechanism. This can lead to inaccurate measurements.

Fluctuations in environmental conditions (temperature, humidity, vibrations, etc.) degrade the performance of the instrument. Example: Using a multimeter in a highly humid environment can degrade its performance. This humidity will induce moisture into its circuit, causing corrosion or altering the electrical properties of components such as resistors and capacitors, ultimately affecting the accuracy of measurements.

Electronic components change their behavior over time. Example: A multimeter being used in a laboratory for years may cause aging and degradation of capacitors and resistors in its circuit, inducing error in voltage measurement.

Continuous use of the instrument may induce mechanical misalignments. Example: A micrometer used in a workshop may develop misalignment between its anvil and spindle due to continuous usage.

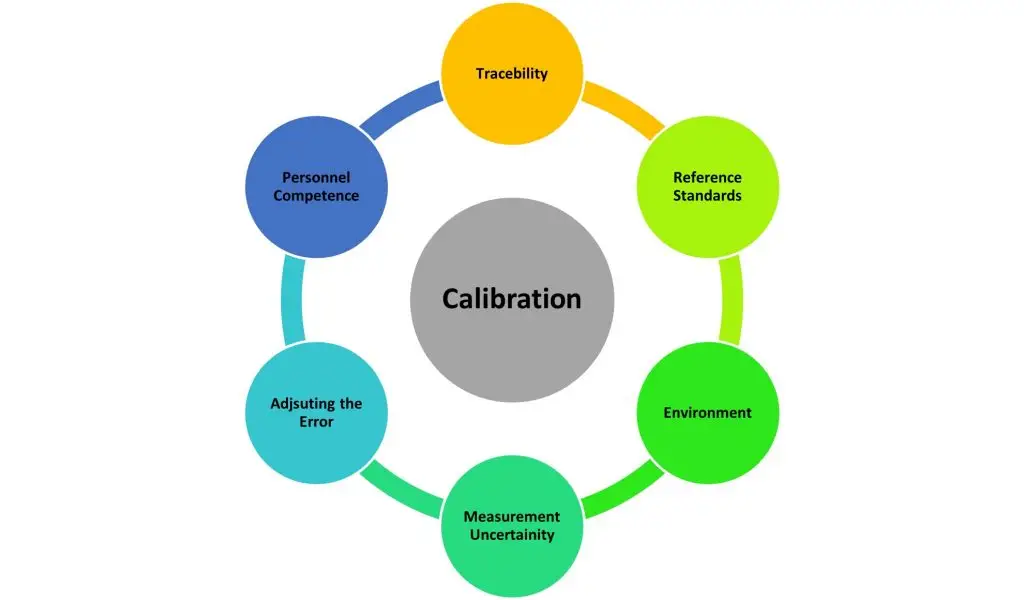

What are the key Pillars of Calibration?

Calibration is a systematic process. Understanding of its core pillars is necessary for ensuring valid calibration results.

Traceability

It is essential that reference standards used to calibrate your instrument are themselves calibrated from higher-level and more accurate standards through an unbroken chain and are finally traceable to national or international standards.

In the case of a Vernier Caliper, gauge blocks shall be calibrated from a higher-level laboratory having a more accurate calibration standard, such as a gauge block comparator, which is further traceable to national or international standards.

Manufacturer produces end product.

Manufacturer inspect and verifies the product with measuring instruments.

Instruments are calibrated by accredited laboratory with their measurement standards.

Their measurement standard is calibrated by a higher level laboratory such as National Metrology Institute (NMI).

NMI’s standards are calibrated NIST using their primary standards.

The NIST standards realize the SI base units.

Reference Standard

Reference standards used to calibrate your instrument shall have higher accuracy than your instrument. The recommended accuracy ratio is ideally 4:1.

Example: Gauge blocks have different accuracy grades, i.e., 00, 0, 1, & 2, with grade 00 being the most accurate. Based on the accuracy specifications, vernier calipers can be calibrated using grade 1 or higher accuracy blocks.

Measurement Uncertainty

Even the most carefully taken measurements are not perfect and are prone to error due to the effect of various factors such as environment, personnel, instrument limitations, etc.

Uncertainty in a measurement is the doubt that exists about a measurement. It involves carefully identifying and quantifying the factors that affect your measurement. Some of the factors that can affect measurements while performing the calibration of a vernier are temperature fluctuations during calibration and limitations of the vernier caliper’s resolution.

Environment

Calibration is always performed in a controlled environment, as factors such as temperature, humidity, atmospheric pressure, etc., can significantly impact the measurement results.

For example, the recommended lab temperature for calibration of a vernier is 20±2 ℃.

Personnel Competence

Trained and competent personnel are pivotal for the correct performance of calibrations. Competence and training records of personnel involved in the calibration of instruments shall be adequately maintained and documented.

Determining & Recording Instrument Error

The objective of calibration is to determine the error in your instrument by comparing its reading with the reference standard’s reading. If the error is small and within the tolerance limit, then your instrument is fine for use.

Adjustment where Required and Feasible

If the error is high and exceeds tolerance limits, then it may be adjusted to reduce the error. However, not every instrument is adjustable. In that case, the instrument may need repair or to be replaced with a new one.

Types of Calibration

There are different types of calibration based on the instrument function. Some important types are as follows:

- Electrical Calibration: Includes calibration of multimeters, power supplies, oscilloscopes, function generators, and frequency counters.

- Dimensional Calibration: Includes calibration of measuring tapes, rulers, vernier calipers, micrometers, plain gauges, thread gauges, dial indicators, etc.

- Pressure Calibration: Includes calibration of pressure gauges, vacuum gauges, pressure transducers, and transmitters.

- Temperature Calibration: Includes calibration of thermometers, thermocouples, RTDs, chambers, ovens, and hot plates.

- Mass Calibration: Involves calibration of weighing balances, weights, load cells, etc.

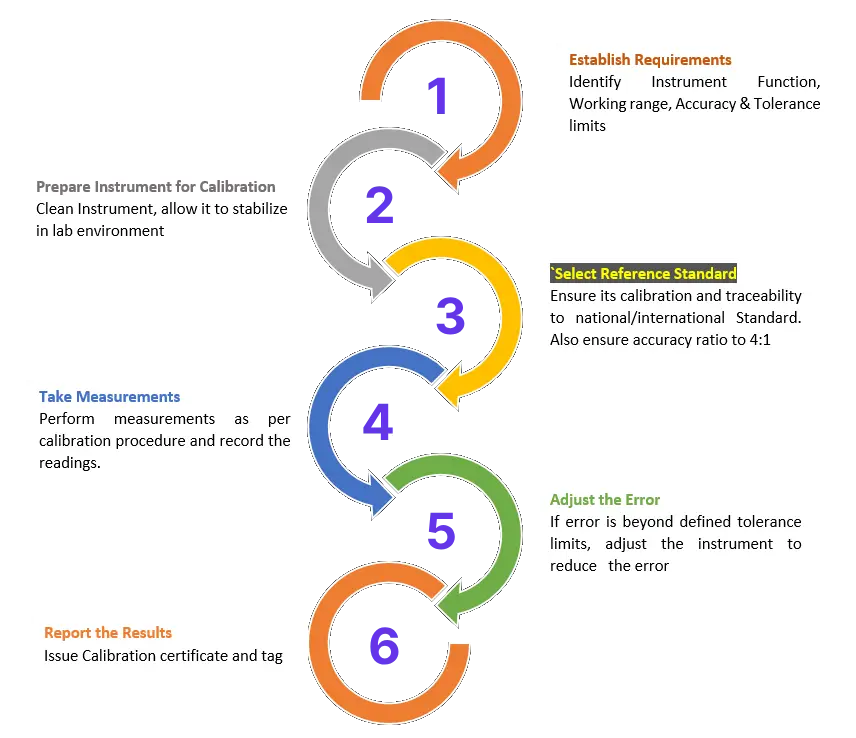

Calibration Process Flow

Establish Requirements

- Ascertain the instrument function(s).

- Identify its measurement range. Choose measurement points covering the full range of the instrument (e.g., for a vernier of size 150 mm, calibration points can be 25 mm, 50 mm, 75 mm, 100 mm, and 150 mm).

- If the operational use of the instrument is limited to a specific measurement point or certain portion of the instrument range, then it is recommended to include it in your calibration procedure. For example, if a vernier caliper is being used in your workshop to measure the thickness of aluminum plates with a nominal thickness value of 10 mm, then it is highly recommended to include 10 mm in your calibration procedure.

- Identify tolerance limits from manufacturer specifications or applicable standards.

Prepare Instrument for Calibration

- Clean the instrument properly.

- Allow proper soaking time for the instrument in the lab environment.

- In case of electrical calibrations, allow proper warm-up time for the instrument and reference standards as mentioned in the calibration procedure.

Select Reference Standards

As discussed earlier, the accuracy of the reference standards should be four times higher than the instrument under calibration, and they should be calibrated from a higher-level reference standard.

Take Measurements

- Perform measurement according to a documented calibration procedure. Record them and calculate the error.

- Prefer standard calibration procedures such as DKD, EURAMET guides, NPL guides, and others.

- In the case of a vernier caliper, you can use procedures in manufacturer manuals, such as the Mitutoyo calibration procedure.

- If no standard procedure is available, then you can develop your own procedure, but it should be properly documented and validated before implementation.

Adjust the Error

- If the instrument is adjustable and the error exceeds the acceptable tolerance limits, then adjust it to reduce the error.

- Recalibrate after adjustment to ensure that the error is within acceptable limits.

- Note the readings before and after adjustment.

Report the Results

Prepare and issue a calibration certificate including:

- Instrument identification (Unique ID, Part No, Serial No, etc.)

- Calibration procedure

- Used reference standards with their traceability

- Environmental conditions

- Measurement results, error, and uncertainties

- Calibration and next due date

- Signature of concerned personnel, i.e., calibration technician, reviewer (supervisor), and approver (manager)

Calibration Process Flow

Calibration is not just a maintenance activity; it is an essential decision-making tool in a Quality Management System based on objective evidence. Calibration gives you confidence that your measuring instruments are accurate, which in turn ensures that:

- Products are inspected accurately

- Processes are controlled efficiently

- Minimal risk of non-conforming product reaching the customer An effective calibration system is critical for the integrity of a QMS. A correlation between QMS standards and calibration is as follows:

ISO 9001:2015

ISO 9001:2015 describes WHAT for an organization. It defines requirements for a Quality Management System of an organization, including requirements related to calibration. It mandates the following for an organization having ISO 9001:2015 certification:

- All instruments or equipment being used in an organization for monitoring and measurement activities shall be calibrated before use and then recalibrated at predefined intervals.

- All calibrations must be traceable to national/international standards.

- All equipment in an organization shall be identified, and their calibration status shall be clearly defined, such as calibrated, due for calibration, limited calibration, etc.

ISO 17025:2017

It describes HOW for calibration laboratories. In contrast to ISO 9001, which defines calibration requirements for an organization, ISO 17025 defines specific management and technical requirements for a calibration laboratory.

In other words, it’s a management system standard for laboratories focusing on their ability to demonstrate their technical competence and production of valid measurement results. The laboratory can be internal within an organization or an external separate entity. Some of its key requirements are:

- Competence of laboratory personnel

- Traceability of measurements

- Environmental control

- Estimation of uncertainty of measurements

- Use of validated/verified calibration methods

- Identification and mitigation of operational risks

- Quality assurance

- Inter-laboratory comparisons

Conclusion

Calibration is not merely a technical requirement; it is a proactive measure to ensure operational reliability and product quality.

By implementing a stringent calibration program ensuring periodic calibration of every instrument in its inventory, an organization can ensure that its instruments provide reliable and accurate measurement data, resulting in better decision-making and quick identification of potential risks.

Frequently Asked Questions (FAQs)

What is calibration of measuring instruments?

It is a process of verifying and adjusting the accuracy of an instrument against a reference instrument or standard.

What is the purpose of calibration of instruments?

Why is calibration important for measuring instruments?

What are the types of calibration for instruments?

What is the calibration process for an instrument?

What is an example of instrument calibration?

How often should instruments be calibrated?

What is the difference between calibration and validation?

What instruments need to be calibrated?

What are the steps in the calibration process?

What is traceability in instrument calibration?

Traceability refers to an unbroken calibration chain linking laboratory standards to national/international standards like NIST.

What a calibration standard is for instruments?

How do you calibrate a measuring instrument?

What is measurement uncertainty in calibration?

What standards apply to instrument calibration?

Calibration Guides and Methods

Calibration Guides and Methods

Learn essential steps and procedures for accurate calibration.

Explore Procedures and GuidesCalibration Tolerances

Calibration Guides and Methods

Dive into the technical specifications, understand acceptable error limits for various types of Measuring and Monitoring Equipment (MMEs), and review industry standards for acceptable calibration error.

View Tolerance DataEnsure your instruments meet ISO 17025 standards and deliver precise, reliable results. Our experts help you maintain accuracy, traceability, and compliance.