Role of Inspection in Quality Control

In aerospace sector even a micron level defect in a critical component like turbine blade, jet engine, landing gear pin, fuselage joint can result in a catastrophic failure. In every value addition process in the industry, cost is involved, and inspections ensure that the defects do not travel down the line.

A defect caught during design phase costs the least to correct. In manufacturing stage the costs increases ten times. If a defect is detected at the assembly stage the cost may be up to 100 times. It is therefore, crucial to detect the defects at every stage of the process and this is ensured through inspection of critical components of the project.

In this article we will look deeper into the role of quality control in the aerospace and automotive sectors. For a complete overview of Mechanical Parts Inspection, read our Comprehensive Guide to Mechanical Parts Inspection.

Distinguishing between good and bad lots

Inspection Sampling

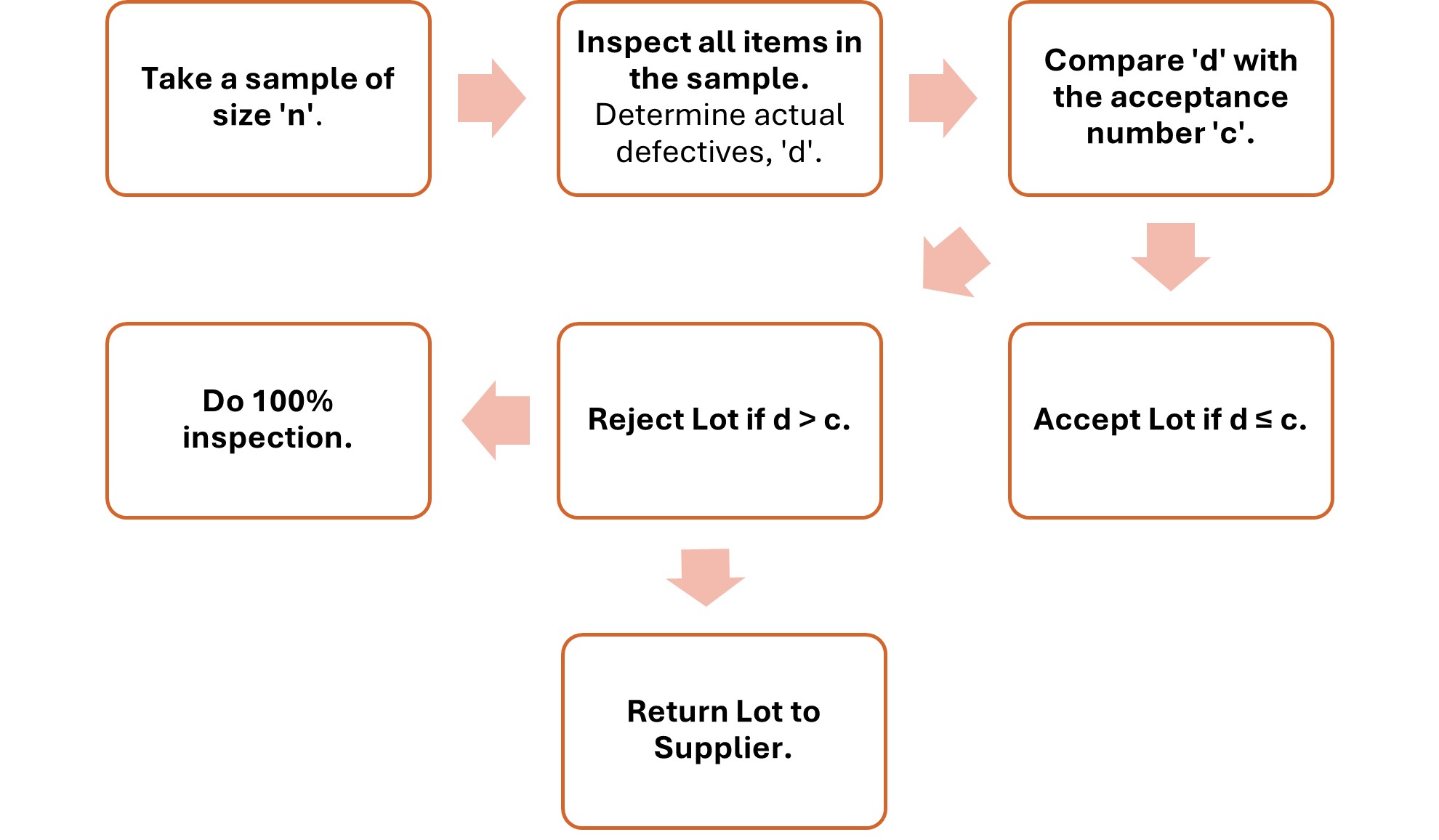

Inspection is mostly carried out on sampling basis to determine if a produced lot is acceptable or unacceptable. The essence of sampling is to check few parts as representative samples of the lot and make a decision on the acceptance or rejection of the entire batch.

To produce an aerospace product, thousands of parts and hundreds of sub-assemblies are typically required. These parts are produced by various vendors and contractors. Acceptance inspection is usually carried out by the parent company when parts are received by the assembly line or by inspection teams deployed at the vendor site. As vendors mature in their quality process the level of inspections required is reduced further.

There are various sampling standards available to suit the specific needs of sampling including MIL-STD-105 (E), ISO 2859, MIL-STD-1916 and ISO 3951. These sampling standards define the rules and acceptance criteria for defective components within a lot.

The standards are based on two types of sampling plans: variable sampling and attribute sampling. Attribute sampling plans indicate the acceptance of the product based on the pass or fail criteria whereas variable sampling plans indicate acceptance through the measurements of quantitative measurement results. For example, the dimension of a part with specified diameter 10 mm should be within tolerance limits of ± 1 mm.

Determine Status of Process Control

One of the most important roles of quality control is to ensure the manufacturing processes are within some stated controls. The controls ensure that the lots will not be produced out of tolerance. This predictive capability is supported by many statistical tools such as control charts, root cause analysis, process capability index, and key performance indicators.

To strengthen process control, vendors are certified to recognized standards like ISO 9001, AS9100, ISO17025, & ISO17020, which require implementation of quality management systems and continuous monitoring.

Engineering Change Management

Another important role of Quality Control is to assist and complement the engineering change management protocols. The Engineering Change is usually managed by Configuration Management Systems usually implemented through modern enterprise solutions such as SAP or Product Lifecycle Management (PLM) systems like IBM’s PLM. However, QC augments these systems by suggesting the changes required in the system and ensuring the mechanism functions effectively throughout the supply chain.

For example, consider the material specification of aluminium alloy 7075. The designer may have specified it in a part drawing and later finalized it. Upon analysis, the quality or engineering team suggests that the hardness of the alloy must meet the T6 condition, otherwise the component could fail. If the original drawing was already communicated to the manufacturer and procurement team, QC plays a vital role in ensuring that the change is relayed effectively so processes can be planned accordingly.

Determination of Technical Evaluations

Quality professionals are directly linked with the customers and receive feedback through established systems to ensure customer satisfaction. Based on customer satisfaction indices and the study of the product performance in the field, quality professionals define the technical evaluations necessary to confirm product performance according to the design specifications.

This is achieved by testing parts, sub assemblies and assemblies against standards such as MIL-STD-810G. This standard outlines a framework for testing products under environmental conditions they are expected to face during operation. While it does not itself certify the products, it provides guidelines for designing test procedures that demonstrate product suitability for a specific environment.

Conclusion

The role of quality control in the aerospace and automotive sectors is therefore not limited to inspection of parts but extends throughout the entire product lifecycle. From detecting defects at the earliest possible stage, to applying sampling standards for acceptance, to ensuring processes remain under control, QC provides the backbone of reliability. It supports engineering changes by keeping the supply chain aligned and ensures that customer feedback is translated into technical evaluations and testing under recognized standards such as MIL-STD-810G.

In essence, quality control ensures that defects are prevented from progressing downstream, processes are predictable, changes are effectively managed, and products are capable of meeting both customer expectations and operational requirements.